User-friendly, big format laminating and mounting. 42 and 60 inch, designed exclusively for the wide format printers. Laminate, mount and encapsulate in one pass up to 1/2 inch thick. No set up change required providing simple operations.

Ledco is known for making machines which are very reliable, easy to use, and inexpensive to maintain.

These units maintain that reputation.

Warranty: Two-year factory warranty

The Digital series "Do It All"

The Digital series were the first designed exclusively for owners of 38 and 50-inch inkjet printers. They do all the finishing tasks required of a large format imaging shop - laminating one side or two, encapsulating, mounting with heat activated (dry mount) or cold pressure-sensitive adhesives (PSA), simultaneous mounting and laminating, and application of cold adhesives.

These machines were made to be very easy to use, incorporating many of the glitch-proof features developed over 40 years of making laminators for schools and commercial finishing shops. These units will laminate one item, then mount and laminate the next in one pass on mounting board up to 1/2-inch thick. No setup change is needed. In fact, you can laminate one item, then mount and laminate the next in one pass without even stopping the machine.

With a top speed of 30 FPM and a sustainable laminating speed of 10 FPM with 5-mil film, the Ledco Digitals are much faster than the other machines made for big format color applications. An optional release liner take-up allows the Digital series to apply cold laminating films, vinyl's and other PSA materials needing removal of a liner.

Easy to use, simple operation with opening and closing rollers for flatter lamination and years of continuous service.

Standard features include variable speed, independent top and bottom heat control, spacious feed tray, powerful film cooling system. The Digital 42 and 60 have swing-away heating units for cold applications and easy cleaning of the rollers.

Ease of use and great for processing heat-activated mounting boards.

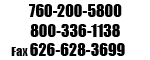

They are shipped fully assembled with a helpful operator's manual and a 90-minute instructional videotape. Ledco provides a toll-free help line to backup the training and support required of its dealers. Customers are encouraged to call so that small problems do not become big ones.

Standard Features and Benefits

- Quality silicone rubber laminating rollers release materials easily and maintain their flexibility for a good edge seal.

- Two sets of rollers keep the film flat and tight while heat laminating so that the automatic fans cool and set the adhesive. When thermal films cool in a slack state, the surface of the lamination is wavy and rippled.

- Supply roll tension is easy to adjust by simply tightening or loosening the tension control knobs on the supply roll mandrels.

- Variable speed allows thinner films to be run faster, and enables mounting or the use of thicker films, which require slower speeds.

- Independent temperature controls for top and bottom heaters allow the use of different materials on front and back of an image.

- Large feed tray makes it easier to handle big graphics. The pressure strip next to the nip helps keep images flat and wrinkle-free.

- Swing away heaters make it very easy to clean the laminating rollers and simplify the use of many cold materials. (Heat shoe and Thermo-glide models)

- Made in the U.S.A. All parts, including motors and controls, are made in the U.S.A. as well!

- All electrical components conform to NRTL standards

Options for the Digital 42 / 60

- Roll feed assembly: The lamination of long images or rolls of images is simplified by a roll feed process. It is difficult to keep long graphics going straight if they are fed from a table. Rolling the material up on an empty core and feeding from a tensioned supply roll with an idler bar insures the material will stay flat and straight from beginning to end.

- Extruded aluminum stand: An extruded aluminum stand is an option on the DI-42, and is standard on the DI-60. Casters are available for either stand, but it is suggested they be removed for stability and safety once the machine is in a permanent location.

- Release liner take-up: This provides for the application of cold (pressure-sensitive adhesive or PSA) laminating films. It is not needed for the application of single-liner cold adhesives.

| Max. Lamination Width |

42" |

| Speed |

0-30 FPM |

| Laminating Roller Diameter |

3" |

| Supply Roll Core Size |

3" |

| Recommended Film |

Up to 10 mil |

| Max. Laminating Thickness |

1/2" |

| Max. Film Roll Diameter |

10" |

| Dimensions (Includes Stand) |

53"L x 26"H x 34"W |

| Shipping Dimensions |

71"L x 43"W x 60"H |

| Weight / Shipping Weight |

480 / 900 lbs |

| Motor |

1/4 HP D/C |

| Electrical (Single Phase) |

208-240V

Single Phase

50-60 Cycle

30 amps |

| Electrical Connector |

NEMA L6-30P |

| Heater |

5200 watts |

Precision Feed Table |

Standard Feed Table |

Click for Digital 42/60 Operation Manual

Click for Checking the Heat Relay

Click for Film suggestions

Click for Digital Series Replacement Parts

42 inch, "F", 1PH, Heat Shoe, Includes stand and casters (42B-0008)

42 inch, "C", 3PH, Heat Shoe, Includes stand and casters (42B-0007)

Roll Feed (8342500)

Release liner take-up 110V (8342000)

Release liner take-up 220V (8342002)

Slitter Assembly When purchase with Laminator (8342600)

Precision Feed Table (8344700)